The History of Copper

The practical use of metal, isolated & modelled through hammering or melting methods is representative of a technical break through achieved in ancient times.

Copper was the first metal mined & crafted by man. It was the most important in history because it was available in great quantities. Initially it was extracted almost at ground surface. It was used to craft weapons, tools, art objects & ornaments.

Excavations have shown that copper crafting is likely to have first happened on the Iranian highlands by Sumerians since the beginning of the Neolithic era. By the end of the fourth millennium BC, use of copper had reached high technical levels in Iran, Mesopotamia & Egypt.

Its use spread across the northern edge of the 'fertile crescent'. Finally it reached the Mediterranean coasts, and to the Trojan site in the west. During the third millennium BC. Troy became very important in metallurgy history as metal craftsmen, merchants & traders established their activity.

From this point, knowledge & materials reached the Aegean Islands & beyond. In particular Crete influenced the spread to islands like Sicily & Sardinia then along European coasts to Spain.

Since about 2000 BC copper crafting was widely diffused in Europe. The Bronze Age began soon after with the development of several important trading routes. The discovery of the process needed to obtain copper from its ores was a very important event in our history. It gave birth to metallurgy & laid the grounds for the development of industry today. Indirectly it also influenced the iron & steel industries.

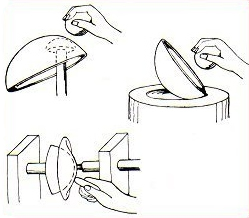

The first copper works were made by cutting, curving & hammering with a stone stroker on a stone anvil: as seen with the Tuscan 'mezzina' crafted in XVIII. Blacksmiths made an important discovery: that metal hardens under prolonged hammering and can be brought back to its original ductility by re heating it. Many ancient objects were manufactured through alternate cycles of hammering & cooking. A final hammering was done to obtain the necessary hardness.

Metal art objects were made by blacksmiths who utilized raw material tin metal foils with various techniques. For example, the simplest way to create a copper bowl consisted in hammering a copper disc placed on a wooden block hollowed to fit the profile of the required object. It is the most ancient method of manufacturing bowls, dating back to pre-dynastic Babilonia & Egypt. Another technique used was known as 'raising'. A tin copper disk, the same diameter as the pot was hammered to get the required shape using an anvil & a suitable hammer.

Embossing became very popular. Hammering the metal foil upside or downside to obtain an embossed decoration. Ancient craftsmen were masters of their craft. They utilized mechanical methods & had great control on raw material during crafting. In particular they had an excellent mastery of the quenching needed to keep the metal ductile & fit for crafting.

As metallurgy evolved, copper was then alloyed with tin to form bronze. This was first obtained by the accidental union of copper and tin minerals inside furnaces. The success of bronze in the ancient world was due to its excellence for casting. For this reason it was brilliantly utilized by artists of the classical age. It was also used in the Middle Ages & in the masterpieces of Renaissance & Baroque.

In modern times copper continues to be used for household objects. Working techniques have remained almost unchanged over the centuries. But shapes have been continuously improved to fit in with evolution of lifestyle. Its properties discovered and appreciated by our ancient ancestors are still valid today.

(sources: Enciclopedia Universale dell'Arte – Artifacts: an introduction to early materials & technology – Ancient Metals)

Tsao-Tsu Cevoli